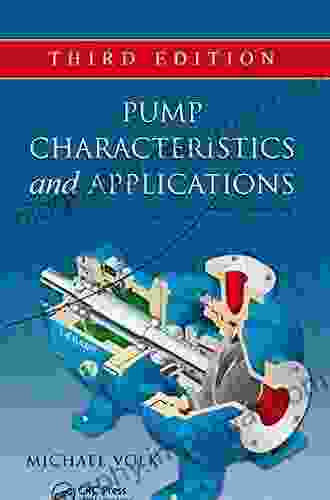

Pump Characteristics and Applications: A Comprehensive Guide for Mechanical Engineers

Pumps are essential components in various industries, including mechanical engineering, fluid mechanics, and hydraulics. They play a crucial role in moving liquids and gases, enabling a wide range of applications. Understanding pump characteristics and applications is paramount for mechanical engineers to optimize pump performance and solve real-world engineering challenges.

This comprehensive guide delves into the fundamentals of pump characteristics and their practical applications in mechanical engineering. We will explore different types of pumps, their operating principles, performance curves, and selection criteria. Furthermore, we will discuss troubleshooting techniques and best practices for maintaining and operating pumps efficiently.

4.3 out of 5

| Language | : | English |

| File size | : | 37428 KB |

| Print length | : | 516 pages |

Types of Pumps

There are numerous types of pumps, each with its unique design and operating principle. The most common types of pumps used in mechanical engineering applications include:

- Centrifugal Pumps: These are the most widely used pumps and rely on centrifugal force to move fluids. They are suitable for handling large volumes of liquids with moderate pressure requirements.

- Positive Displacement Pumps: These pumps displace a fixed amount of fluid with each cycle. They are ideal for applications requiring high pressures or precise flow control.

- Reciprocating Pumps: These pumps use a piston or diaphragm to move fluids. They are commonly used in applications where high pressures are needed.

- Jet Pumps: These pumps utilize the Venturi effect to move fluids. They are often used in applications where high suction lifts are required.

Pump Operating Principles

Each type of pump operates on a specific principle to move fluids. Here's a brief overview of the operating principles of different pump types:

- Centrifugal Pumps: Centrifugal pumps use an impeller rotating at high speeds to impart centrifugal force to the fluid. This force pushes the fluid outward from the impeller, creating a pressure difference that draws more fluid into the pump.

- Positive Displacement Pumps: Positive displacement pumps use a rotating or reciprocating element to trap and move a fixed amount of fluid with each cycle. This type of pump can generate high pressures but typically has lower flow rates.

- Reciprocating Pumps: Reciprocating pumps utilize a piston or diaphragm to move fluids. As the piston or diaphragm moves, it creates a suction that draws fluid into the pump and discharges it when the piston or diaphragm moves in the opposite direction.

- Jet Pumps: Jet pumps use a high-velocity fluid stream to create a low-pressure area that draws fluid from a separate source. This type of pump is often used in applications where high suction lifts are required.

Pump Performance Curves

Pump performance curves are essential tools for understanding the characteristics and capabilities of a pump. These curves provide valuable information about the pump's flow rate, head, power consumption, and efficiency at different operating conditions.

- Flow Rate Curve: This curve shows the relationship between the pump's flow rate and the head. It indicates the maximum flow rate the pump can deliver at a given head.

- Head Curve: This curve shows the relationship between the pump's head and the flow rate. It indicates the maximum head the pump can generate at a given flow rate.

- Power Curve: This curve shows the relationship between the pump's power consumption and the flow rate. It indicates the power required to operate the pump at different flow rates.

- Efficiency Curve: This curve shows the relationship between the pump's efficiency and the flow rate. It indicates the pump's operating efficiency at different flow rates.

Pump Selection

Selecting the appropriate pump for a specific application requires careful consideration of several factors, including:

- Flow Rate Requirement: Determine the required flow rate for the application. This will help narrow down the available pump options.

- Head Requirement: Determine the required head for the application. This will ensure the pump can generate sufficient pressure to overcome system resistance.

- Fluid Properties: Consider the properties of the fluid being pumped, such as viscosity, density, and temperature. This will impact the pump's performance.

- System Requirements: Take into account any specific system requirements, such as suction lift, discharge pressure, and operating conditions.

- Performance Curves: Utilize pump performance curves to compare different pump options and select the one that best meets the application requirements.

Pump Troubleshooting

Pumps can encounter various problems during operation. Common troubleshooting techniques include:

- Checking for Leaks: Inspect the pump for any leaks that may be reducing performance or causing damage.

- Verifying Power Supply: Ensure the pump is receiving the correct power supply and that the motor is functioning properly.

- Inspecting Impeller and Casing: Examine the impeller and casing for any damage or wear that may be affecting pump performance.

- Monitoring Temperature: Check the pump's temperature to identify any overheating issues that may need to be addressed.

- Analyzing Pressure Gauges: Use pressure gauges to monitor the pump's suction and discharge pressures and compare them to the expected values.

Best Practices for Pump Maintenance and Operation

To ensure optimal pump performance and longevity, follow these best practices:

- Regular Inspections: Perform regular inspections to identify any potential issues and address them promptly.

- Scheduled Maintenance: Follow the manufacturer's recommended maintenance schedule to keep the pump in good working condition.

- Proper Lubrication: Ensure the pump is properly lubricated as per the manufacturer's instructions.

- Avoiding Cavitation: Operate the pump within the recommended flow rate range to prevent cavitation, which can damage the pump.

- Protecting from Overheating: Monitor the pump's temperature and implement measures to prevent overheating.

Understanding pump characteristics and applications is essential for mechanical engineers to design, operate, and maintain efficient pumping systems. By carefully selecting the appropriate pump for the application and following best practices for maintenance and operation, mechanical engineers can optimize pump performance and ensure the efficient movement of fluids in various engineering systems.

This comprehensive guide has provided an in-depth overview of pump characteristics and applications in mechanical engineering. For further exploration, you can refer to specialized textbooks, technical papers, and industry resources to expand your knowledge and stay abreast of the latest advancements in pump technology. By mastering this critical aspect of mechanical engineering, you can contribute to the development and operation of

4.3 out of 5

| Language | : | English |

| File size | : | 37428 KB |

| Print length | : | 516 pages |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Book

Book Novel

Novel Page

Page Chapter

Chapter Text

Text Story

Story Genre

Genre Reader

Reader Library

Library Paperback

Paperback E-book

E-book Magazine

Magazine Newspaper

Newspaper Paragraph

Paragraph Sentence

Sentence Bookmark

Bookmark Shelf

Shelf Glossary

Glossary Bibliography

Bibliography Foreword

Foreword Preface

Preface Synopsis

Synopsis Annotation

Annotation Footnote

Footnote Manuscript

Manuscript Scroll

Scroll Codex

Codex Tome

Tome Bestseller

Bestseller Classics

Classics Library card

Library card Narrative

Narrative Biography

Biography Autobiography

Autobiography Memoir

Memoir Reference

Reference Encyclopedia

Encyclopedia Paul Dawson

Paul Dawson Frank Benischeck

Frank Benischeck John Ross Bowie

John Ross Bowie Robert S Miller

Robert S Miller Dianna Lefas

Dianna Lefas Le Ly Hayslip

Le Ly Hayslip Andrew Klavan

Andrew Klavan Tee L Guidotti

Tee L Guidotti 2014th Edition Kindle Edition

2014th Edition Kindle Edition Joseph H Di Leo

Joseph H Di Leo Michael Christopher Low

Michael Christopher Low Jon Bowman

Jon Bowman Phildar

Phildar Marty Snyderman

Marty Snyderman Helen Kleberg Groves

Helen Kleberg Groves Jennifer Scanlon

Jennifer Scanlon Michela Balconi

Michela Balconi David Day

David Day Chris Mcnab

Chris Mcnab Allan Mccay

Allan Mccay

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Cameron ReedCook with Confidence: '101 Healthy Recipes for the Busy or the Lazy' - Your...

Cameron ReedCook with Confidence: '101 Healthy Recipes for the Busy or the Lazy' - Your...

Christian CarterDiscover the Intriguing History of Virginian Agriculture: A Journey from 1607...

Christian CarterDiscover the Intriguing History of Virginian Agriculture: A Journey from 1607...

Clinton ReedAbsorption Chillers and Heat Pumps: Unleashing the Power of Energy Efficiency

Clinton ReedAbsorption Chillers and Heat Pumps: Unleashing the Power of Energy Efficiency Dominic SimmonsFollow ·4.4k

Dominic SimmonsFollow ·4.4k Charlie ScottFollow ·11.8k

Charlie ScottFollow ·11.8k Ernest PowellFollow ·18.2k

Ernest PowellFollow ·18.2k Felipe BlairFollow ·13k

Felipe BlairFollow ·13k Eliot FosterFollow ·19.8k

Eliot FosterFollow ·19.8k Alfred RossFollow ·4.4k

Alfred RossFollow ·4.4k Ibrahim BlairFollow ·11k

Ibrahim BlairFollow ·11k Brady MitchellFollow ·8.7k

Brady MitchellFollow ·8.7k

Jeff Foster

Jeff FosterExploring Culture: Exercises, Stories, and Synthetic...

Culture is a complex and multifaceted...

Eddie Bell

Eddie BellPrinciples of ICD-10 Coding Workbook: Your Comprehensive...

Empower Yourself with the...

Nikolai Gogol

Nikolai GogolOttoman Egypt: A Catalyst for the Modern World's...

: A Hidden Gem in...

Jorge Amado

Jorge AmadoUnveiling the Secrets of Group Intervention: A...

In the realm of...

Dakota Powell

Dakota PowellUnveiling the Interwoven Nature of Animality and Colonial...

Welcome to an...

4.3 out of 5

| Language | : | English |

| File size | : | 37428 KB |

| Print length | : | 516 pages |